Improving industrial energy efficiency at the European Manufacturing level requires the integration of energy data with advanced optimization techniques to guide a company decision making.

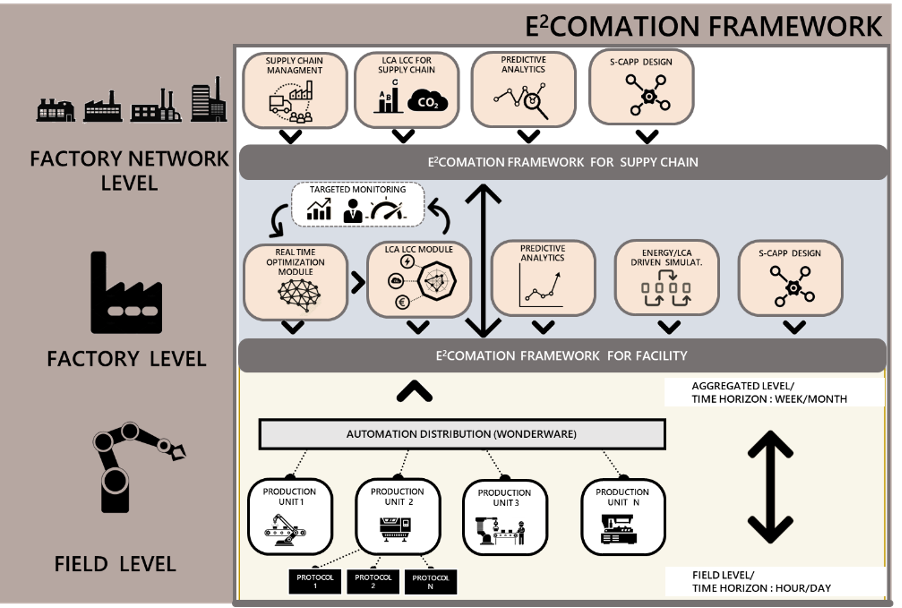

E2COMATION intends to address the optimization of energy usage, at multiple hierarchical layers of a manufacturing process as well as considering the whole life-cycle perspective across the value chain.

Nowadays, there is a great effort to adopt and use of alternative and renewable energy sources, like wind, solar, hydrogen, etc., but unfortunately for disparate reasons they are not enough or applicable. For such reasons, there must also be an effort in the industrial sector in order to reduce the consumption and the request of energy, minimizing in this sense the damage caused by the use of fossil fuels.

To this purpose, E2COMATION project, providing a cross-sectorial methodological framework and a modular technological platform, is meant to help industrial companies saving energy and directly being more sustainable from the environmental and economic point of view

E2COMATION provides benefits not just regarding sustainability aspects but also related the efficiency. All the efforts regarding energy efficiency research imply a change, improvement and efficiency in the company as a whole. As an example, the affected areas of this efficiency rising could be the scheduling of recourses, orders forecasting, production plans, clear vision and control across the whole value chain.

The solutions that will be developed in the E2COMATION framework will operate at all factory levels, from collecting information and data at field level, to managing and optimizing production at factory level, and even up to factory network level.