One goal of E2COMATION is proposing and validating a generic and adoptable IT infrastructure to address and optimize the resource and energy efficiency in industrial production. The outcome is a layered architecture, shown below, where the individual layers can be freely distributed either on premises or in the cloud.

Data is flowing from bottom to top, firstly collected at the shop floor, and then aggregated in the CPS-izers Layer shown in light green. To achieve the decoupling of the upper two layers we use industry standard MQTT brokers for a flexible publish/subscribe mechanism. This allows each component to decide for itself what data they need for their task.

The central component in the DSC Layer, the layer that uses the aggregated data from the shop floor and connects it with other relevant production parameters, e.g. from MES or SCADA systems, is the real-time processing engine Apama. It is a commercial product from Software AG and was first used in fraud detection scenarios in the banking and telecommunication sectors. However, real-time detection of anomalies becomes more and more important for industrial production processes as well to save time and money. For our use cases the Community Edition, see https://apamacommunity.com, is sufficient and freely usable.

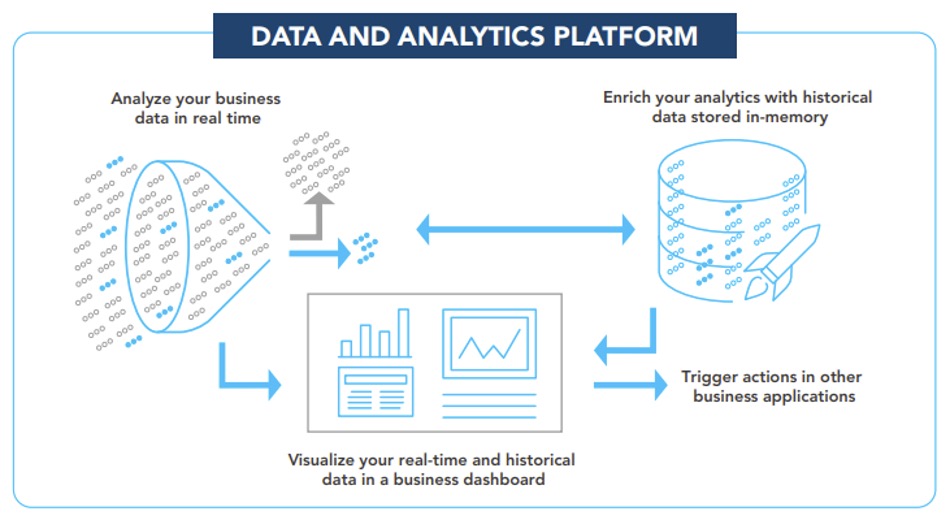

The general usage patterns of Apama are given in the figure below which are:

- Analyze your business data in real time

- Enrich your analytics with historical data

- Visualize your real-time and historical data in business dashboards

- Trigger actions through detection of pre-defined conditions

An important role for Apama in the E2COMATION platform is the triggering part which is used to inform the Digitals Twin models or the Plant Simulation models that the shop floor values have so significantly changed that an update of the models is needed. The triggering condition can be written in many different ways, e.g. in Apama’s own Event Processing Language (EPL) or in other supported languages like Java, C++ or Python. In addition, support is given via an additional component for industry-standard Machine Learning (ML) models in PMML or ONNX format.

Since the triggering conditions can be adopted to any use case the proposed architecture including Apama is suitable to address all of E2COMATION use cases.